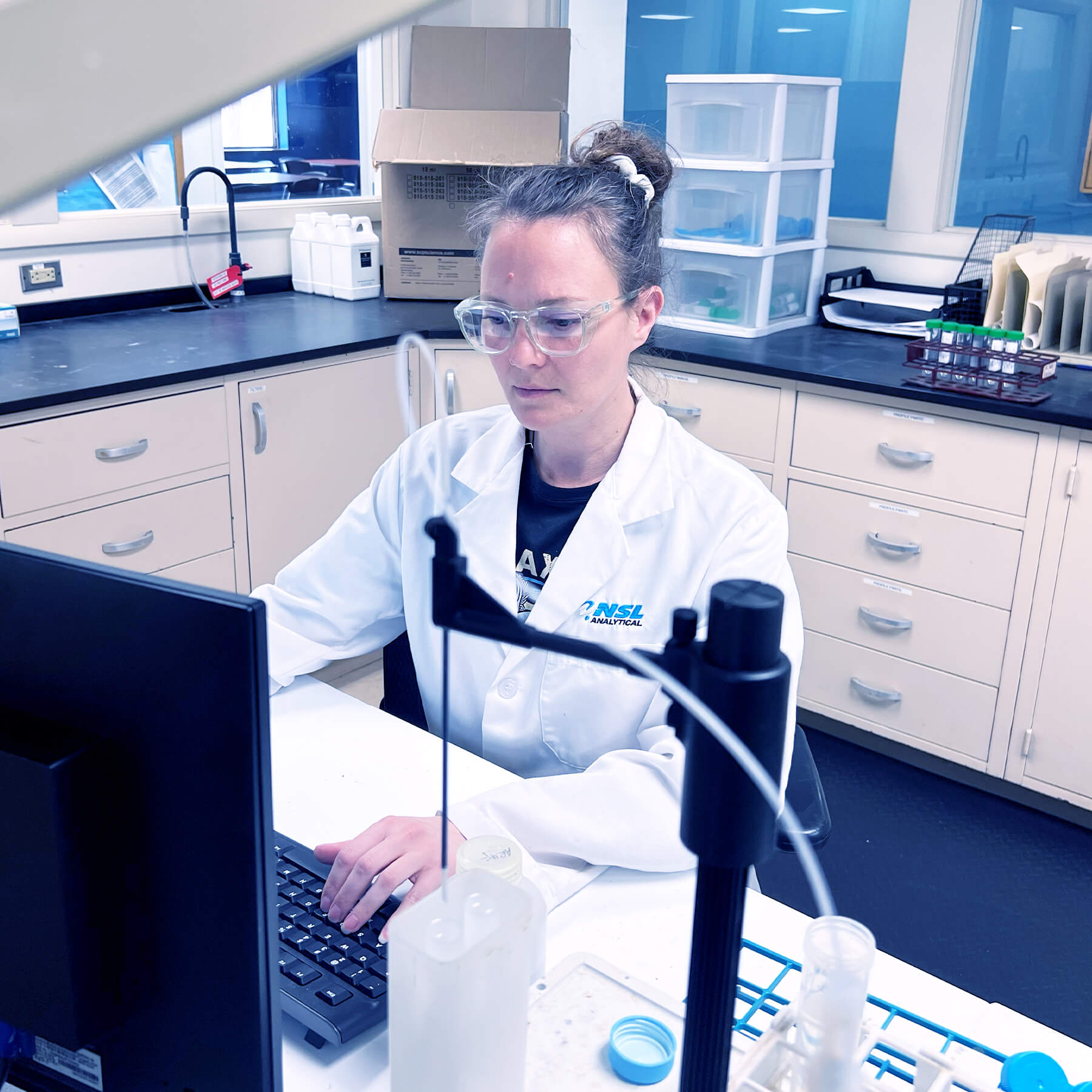

Some of NSL Analytical’s customers consistently use materials that are regulated by governmental agencies. These companies must be able to prove, with detailed records and documentation, that their products meet all regulations.

NSL Analytical understands and applies the appropriate regulations.

Consumer Product Safety Improvement Act (CPSIA) of 2008 is one of the most comprehensive transformations of consumer-product safety regulations since the 1970s. CPSIA expands the role of the Consumer Product Safety Commission (CPSC) in ensuring the safety of consumer products, especially those designed for children. NSL is approved under CPSC to test for the determination of phthalates, children’s jewelry, children’s metal products, children’s non-metal products, lead paint regulation.

Manufacturers, importers and retailers of most consumer products have to comply with many provisions of CPSIA, including:

According to regulations, periodic testing must be performed by a CPSC-accepted third-party laboratory. The staff at NSL is thoroughly familiar with all these regulations and would be happy to ensure the compliance of your product.

NSL tests for hazardous materials listed in RoHS, WEEE, Prop 65, and CPSIA.

Some of the many NSL analysis techniques for regulated substances

| Test Methods | ||||

|---|---|---|---|---|

| Test technique | Substances | Polymers | Metals | Homogeneous electronic components |

| Mechanical preparation | All | Direct measurement Grinding |

Direct measurement Machining |

Grinding |

| Chemical preparation | All | Microwave digestion Acid digestion Dry ashing Solvent extraction |

Acid digestion | Microwave digestion Acid digestion Solvent extraction |

| Analytical methods | PBB/PBDE | Gas chromatography/mass spectroscopy (GCMS) Liquid chromatography (LC) |

— | Gas chromatography/mass spectroscopy (GCMS) Liquid chromatography (LC) |

| Cr (VI) | Colorimetry | Colorimetry | Colorimetry | |

| Hg | Inductively coupled plasma (ICP) / atomic emission spectroscopy; ICP/mass spectroscopy; cold vapor atomic absorption spectroscopy; atomic absorption spectroscopy. | |||

| Pb/Cd | X-ray fluorescence (XRF); ICP/mass spectroscopy; ICP/atomic emission spectroscopy; atomic absorption spectroscopy. | |||

When the laboratory knows all of the many exemptions to the regulations, you can save time and money. Some examples of exemptions:

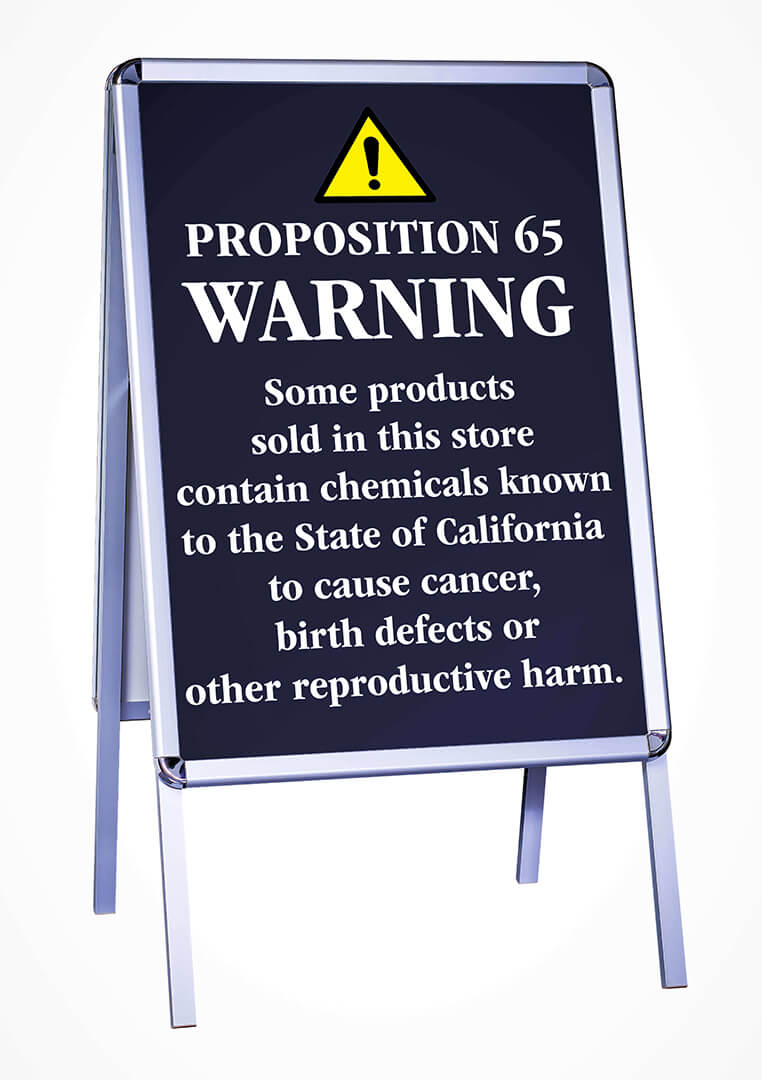

The California Proposition 65 statute states that no person in the course of doing business shall “knowingly and intentionally expose any individual to a listed chemical” without first giving a clear and reasonable warning. The governor of California is required to publish annually a list of chemical substances that the state has determined to either cause cancer or cause birth defects or other reproductive harm.

Manufacturers and distributors of products in or to the state of California must identify and properly label the chemical substances found in their product. Examples are heavy metals like lead, fire retardants, and plasticizers such as phthalates. In addition, for products such as carpets, volatile organic compounds (VOC) emissions must be limited.

View our Ophthalmic Testing Services page for specific California Prop 65 information. Steve Ross, Ophthalmic Representative at NSL, shares an informative overview regarding “The Ever Changing Face of Safety Regulations in America” for the ophthalmic industry.

NSL’s in-house laboratories are equipped with the latest equipment for testing chemical content specific for the Proposition 65 label and content law.

In addition to individual elements and testing NSL has created specific bundles.

CALIFORNIA PROPOSITION 65 NOTICE. Testing done by NSL for purposes of California’s Proposition 65 (Prop 65) requirements will be based on information and test limits currently available to the public at the time of testing. NSL testing and analysis will show the percentage of existence and/or the absence of certain compounds or elements, but NSL cannot certify compliance with Prop 65 law. NSL test results do not alleviate customer’s responsibility for Prop 65 labeling, if necessary. NSL will not make any recommendations or opinions on whether labeling is necessary. For more information on Prop 65, please click here.

NSL provides RoHS and WEEE materials testing services for electronic equipment to ensure compliance with current industry regulations.

The European Union’s Restriction of Hazardous Substances (RoHS) Directive requires suppliers of electronic equipment to guarantee that the entire unit is free of:

Therefore, materials testing of electronic components is required to ensure compliance.

The RoHS 2 Directive took effect January 2, 2013. This “RoHS-recast” was done primarily to provide greater clarity in definitions and rules. The regulations are basically unchanged from the original RoHS, except that its requirements are gradually extended to include all electrical and electronic equipment, including cables and spare parts medical devices, industrial instruments, and monitoring and control instruments by July 2019. It also includes a “methodology for the assessment of new hazardous substances” to meet waste-related criteria.

RoHS 2 requirements will extend to the new product categories on the following dates:

Download a complimentary RoHS white paper, A Rose is a Ross, for more information about RoHS is and what it means to you.

The Waste Electronic and Electrical Equipment (WEEE) directive covers equipment that depends on electrical current or electromagnetic fields in household appliances, computers, light bulbs, phones, and other similar products. Like RoHS, its goal is to reduce introduction of hazardous materials into the environment during recycling or disposal.