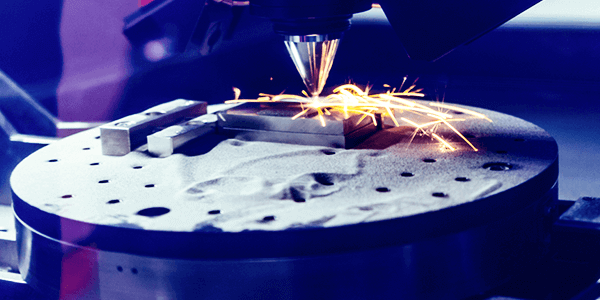

Qualification of materials made by additive manufacturing is an essential step toward moving to the production of parts for regulated industries.

This is a thorough process requiring many tests to be completed in order to set standards that validate the printed material. It also points the way toward reliable and consistent industrial additive manufacturing.

The challenge of material qualification is that it can take years to complete. The process can also be expensive, with the spend to qualify a new metal alloy and machine potentially landing in the millions of dollars.

Delta Qualification provides a strong alternative.

Often referred to as Delta-Qual, it is one method to address the time and cost issues associated with validating pathways by which new equipment can be qualified.

With this approach, existing materials chemistry and mechanical property design curves are used as a baseline. Then new machines or machines moved into new facilities can produce parts with statistically comparable properties.

If Delta-Qual is properly implemented, it can be an important part of responsibly decreasing time to market for new production metal printing.

NSL Analytical is providing chemistry, microstructure, and properties testing for materials manufacturers, machine OEMs, and parts producers in the industrial printing space. This includes services such as metal powder and additive manufacturing parts producers.

In addition, NSL Analytical is part of a project team that was recently awarded a grant from the US Air Force through America Makes in order to establish standards for the Delta-Qual of metal printed titanium.

To learn more about NSL Analytical, our materials, industries, and testing services, visit nslanalytical.com.

LOS ANGELES – June 27, 2024 – Levine