NSL Adds New Testing Capabilities to ISO 17025 Accreditation

NSL Analytical Services, an independent commercial testing laboratory in Cleveland, Ohio has continued to expand their analytical testing services. NSL has added X-Ray Diffraction (XRD) analysis and Liquid Chromatography with tandem Mass Spectroscopy (LC-MS/MS) to their ISO 17025 accreditation scope, along with adding a new version of their Fourier-Transform Infrared (FTIR) Spectrometer instrument.

X-Ray Diffraction for Analysis

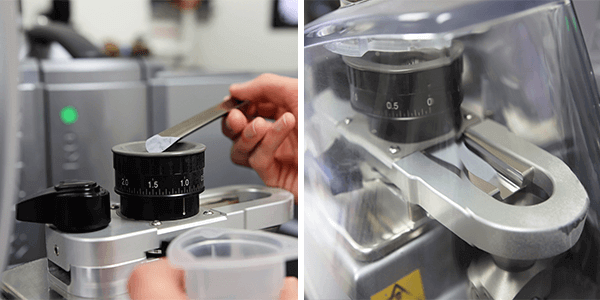

XRD analysis is a means of structural, non-destructive ceramic analysis. NSL recently acquired an Rigaku MiniFlex X-Ray Diffraction (XRD MiniFlex) to offer this testing method. The XRD MiniFlex provides material composition identification, quantitative estimation, and crystal structure analysis.

XRD analysis also helps bolster NSL’s ceramic analysis capabilities because it complements their X-Ray Fluorescence (XRF) spectrometer. While XRF spectroscopy provides quantitative elemental composition of materials, it cannot distinguish between identical atoms in different crystalline phase arrangements. Now, NSL can now confirm both the elemental and phase content by combining XRF analysis with XRD analysis.

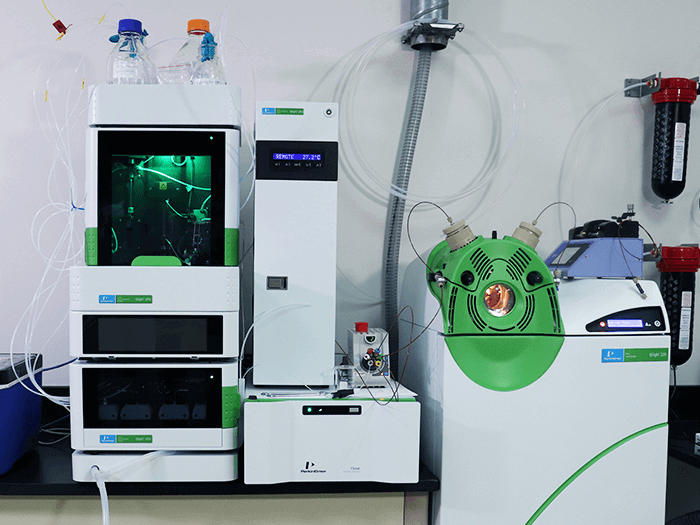

New Polymer Testing Capabilities

NSL’s new LC-MS/MS and FTIR help to further expand NSL’s myriad of polymer testing services. Their new, top-rated LC-MS/MS system incorporates Ultra High Pressure Liquid Chromatography (UHPLC) with a dual-source, triple quadrupole mass spectrometer. This polymer lab equipment allows for precise measurements of very low concentrations of organic species in a wide range of sample types. NSL is initially deploying this technique to measure ppb levels of polyfluoroalkyl substances (PFOS/PFOA) in manufactured materials.

Meanwhile, NSL has added the world-class Perkin Elmer FT-IR Spectrum 3 to their polymer testing laboratory as well. This high-tech system allows NSL’s scientists to perform FTIR services for samples ranging from 4,000-450 cm-1. Sample applications include, but are not limited to polymers, chemicals, pharmaceuticals, and nutraceuticals.

Expansion of Accreditation Scope

As a recognized leader in analytical testing, NSL is committed to providing trusted technology and testing services that offer timely, repeatable results. “These additions to our accreditation scope help us expand our wide array of analytical testing capabilities,” said Ron Wesel, NSL’s CEO. “The combination of this new instrumentation and the expertise of our scientists allows us to provide our customers with the most accurate, wide-ranging, and timely services available.”

Learn More About These New Capabilities

Contact us to discover more about the capabilities of these technologies. As a recognized leader in analytical testing, NSL would be happy to help address your testing needs. Since 1945, NSL has helped to verify the highest quality, performance, and safety standards in product materials through comprehensive testing services.

Recent Posts

Levine Leichtman Capital Partners Acquires NSL Analytical Services

LOS ANGELES – June 27, 2024 – Levine

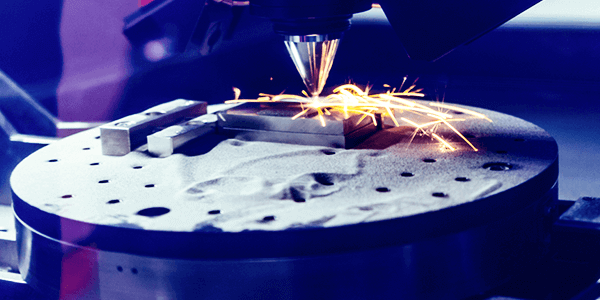

NSL Analytical Offers Delta Qualification to Speed Up Parts Production Through Additive Manufacturing

Qualification of materials made by additive manufacturing is