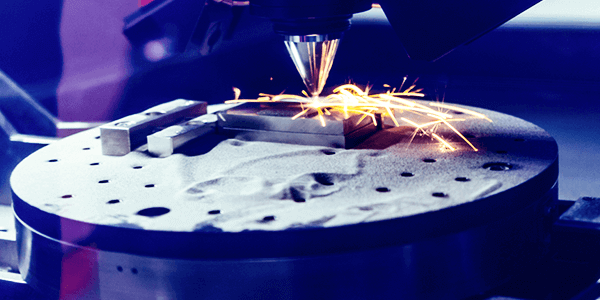

A research group unveiled a medical 3D printing discovery in The International Journal of Molecular Sciences. They published the discovery of a 3D-printable antiviral material in an article titled “3D Printed Cobalt-Chromium-Molybdenum Porous Superalloy with Superior Antiviral Activity”. They discovered that the porous Cobalt-Chromium-Molybdenum (Co-Cr-Mo) superalloy is potent with antiviral properties. These properties that can help in the fight against COVID-19, regardless of variant. The Co-Cr-Mo alloy is now the preferred use in comparison to the common antiviral metals, such as silver and copper.

The project was led by Dr. Arun Arjunan, Dr. Ahmad Baroutaji, and John Robinson, from the University of Wolverhampton, Telford, United Kingdom, along with help from other colleagues in the field. First, they assessed the antiviral performance of different additively-manufactured materials. They discovered that the material could offer the potential for preventative virus transmission and immediate manufacturing. This major scientific discovery could potentially help decrease the number of infected people. IT could also help drastically decrease the number of hospitalizations. Most medical instruments consist of surgical steel, which is silver and copper. By 3D printing with this new antiviral material it could prevent the spread of viral infections, they concluded.

Antiviral materials such as Co-Cr-Mo offer “much potential for transmission prevention”, said Dr. Arun Arjunan. “Airborne droplets below five microns can contain infectious SARS-CoV-2 and can remain suspended in the air for three hours, masks do offer some protection from the transmission. Surfaces, on the other hand, can sustain infectious viruses from a few hours to nine days depending on the surface material and morphology. For example, stainless steel that is widely found in hospitals and medical settings can sustain SARS-CoV-2 survival for seven days.”

Lead researcher John Robinson said that the Co-Cr-Mo material has “potent antiviral activity”, showing significant improvement over copper and silver alloys, that have antimicrobial properties. “To our knowledge, we are the first to assess the anti-SARS-CoV-2 efficacy of Co-Cr-Mo which displayed 100% viral inactivation in 30 minutes,” he said. These conclusions bolster the material’s medical 3D printing potential in the fight against COVID-19.

The antiviral properties and proven anti-SARS-CoV-2 efficacy of Co-Cr-Mo offer great potential for medical 3D printing. According to John Robinson, Co-Cr-Mo could be adopted for antiviral mask filters. Additionally, it could also be used in heating, ventilation, and air conditioning filtration systems for healthcare and general community settings. “Additionally, we could use Co-Cr-Mo for door handles or other touch points to reduce or eliminate a high potential for virus transmission,” said John Robinson. At NSL, we are excited for the potential of this new material in the fight against COVID-19.

At NSL, our team of scientists has experience with metallurgical testing and powder characterization, and chemical analysis of superalloys. To learn more about this new discovery or about testing for 3D printing or additive manufacturing in general, please contact us. Our scientists would be happy to assist you.

LOS ANGELES – June 27, 2024 – Levine

Qualification of materials made by additive manufacturing is