Additive Manufacturing Networking Event Concluded

“The amount of AM knowledge in the room was off the charts and exceeded my expectations!”

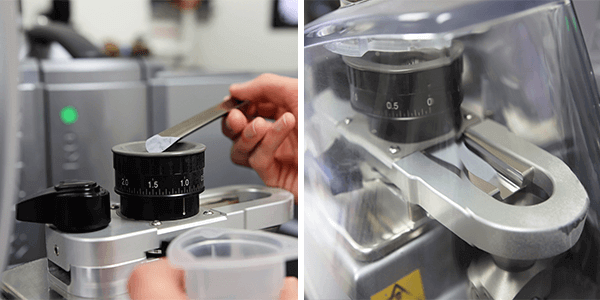

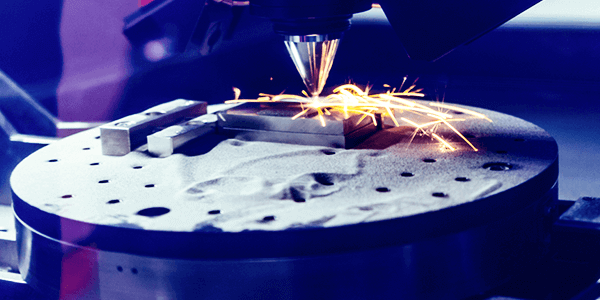

Additive manufacturing (AM) also known as 3D printing, can be used to create almost anything out of various plastics, metals or ceramic materials. It’s a tremendous opportunity for manufacturers and engineers but it doesn’t come without its challenges. Every stage of the AM ecosystem has the potential for quality issues which makes materials testing vital.

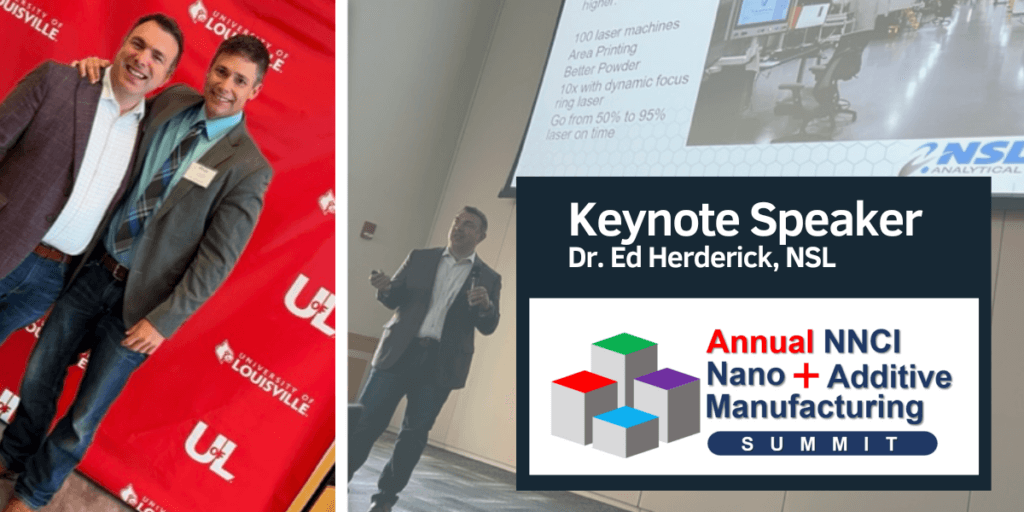

Last week, NSL sat down with a group of industry experts to discuss The Importance of testing in AM. In partnership with Northeastern Ohio Women in 3D Printing (Wi3DP), we hosted several people from the local AM community to allow for networking and the opportunity to interact with industry AM leaders Humna Khan (ASTRO Mechanical Testing Laboratory), Robert Bianco (Eaton) and Gert-Jan H. Nijhuis (The Lubrizol Corporation).

After a tour of our Analytical Laboratory, Ed Herderick, NSL’s Vice President of Science & Technology, led the panel discussion with the attendees. The panel covered the latest in AM materials and process industrialization. Views on the current state of the art and future needs around materials development, testing, and qualification were discussed as well as where the transition to production for industrial AM is heading.

“AM printing technology is going through an exponential development period with myriad new materials development approaches coupled with exciting new process improvements. Taken together a new phase of industrial application expansion of its use is happening. The key to unlocking this potential is increasing the confidence and speed of deployment for new process and alloy combinations. The foundation for doing that is creation of salient materials data sets that inform the use of AM printed materials for specific applications.”

Ed Herderick,

Vice President of Science & Technology, NSL

“Such a great event! NSL was thrilled to partner with NE Ohio Wi3DP and the phenomenal panel that was put together, you could feel the energy throughout the day. Thoughtful questions were asked, and engaging discussion followed during both the panel talk and laboratory tours. The energy was electric!”

Gina Sich,

Business Development Manager, NSL

Throughout the discussion with the panel a few key messages kept popping up. The first, the importance of speed to having data, and how critical it is to have timely support (materials testing, processing parameters, dimensional analysis, non-destructive evaluations) in order to move into production. The second evident takeaway was collaboration. Throughout the stages of choosing the material type, finalizing the part design and then 3D printing you must develop partnerships that will lead to the best business outcomes.

NSL would like to thank the NE Ohio Wi3DP Chapter for their commitment and support in preparing for this event and allowing us to host it. After the event ended, Cynthis Rogers, Co-President, NE Ohio Wi3DP Chapter said, “Dang – this was so good – AM education and networking in Cleveland! Northeast Ohio Women in 3D Printing hosted this gathering at NSL Analytical Services, Inc., culminating in one of the best panel discussions I’ve heard on materials and collaboration in AM.”

AM provides the opportunity for manufacturers to produce complex near-net shape parts and components quicker and more efficiently. Once used primarily for prototyping, this technology is growing across almost all industry verticals. Our laboratory is working with clients in aerospace, space, automotive, power generation, consumer goods as well as medical device. We provide advanced material testing to ensure the AM process stays within quality control and complies with the various industry QA standards and requirements. As the technology of AM evolves, NSL will continue to educate industry and collaborate with front-runners in the additive manufacturing market.

Follow #nslanalytical on LinkedIn for upcoming events and industry news.

Watch our short montage video!

NSL would like to share a short video of event highlights from June 14th, 2023. Once again, thank you to our panelists, WI3DP, presenters, those who helped organize this event and our attendees.

Recent Posts

Levine Leichtman Capital Partners Acquires NSL Analytical Services

LOS ANGELES – June 27, 2024 – Levine

NSL Analytical Offers Delta Qualification to Speed Up Parts Production Through Additive Manufacturing

Qualification of materials made by additive manufacturing is