Even with the use of existing standards, several notable gaps remain.

October 1, 2019

Dave van der Wiel

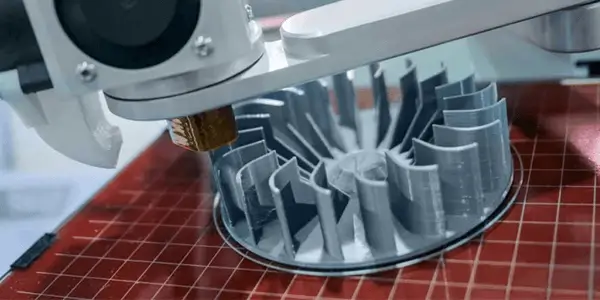

Materials testing in metal additive manufacturing (AM) involves characterization of raw materials and evaluation of finished parts. The raw materials used in metal AM processes include powders, laments and sheets. Powders are utilized in many AM processes, most notably powder bed fusion (PBF), while laments are used in extrusion and certain deposition processes, with sheets used for lamination processes.

The rapid pace of adoption of AM processes by industry has created a serious gap in standardization of materials, processes, test methods and design. The largest uni ed AM standardization effort involves a joint effort between the AM committees of ASTM F42 and ISO TC 261. Joint ISO/ASTM standards will be published as European standards (EN) through collaboration with the European Committee for Standardization (CEN).

Under a joint effort between ANSI and America Makes, the Additive Manufacturing Standardization Collaborative (AMSC) published a Standardization Roadmap for AM in 2018. This publication includes gap analyses for materials testing of raw materials and finished parts, along with then-current efforts aimed at mitigating those gaps. Critical to ASTM-ISO AM efforts are several data-producing R&D projects within the ASTM AM Center of Excellence (COE) as well as at supporting organizations such as NIST and the Additive Manufacturing Consortium (AMC).

Raw Materials

Analyses of filament and sheet type metal feedstocks is already standardized outside the AM space, and so these raw materials typically do not present unique challenges to standardized testing. However, because of very high surface area to volume ratios, powder materials often display unique properties that depart from those of bulk forms. These properties, in turn, affect intraparticle forces with bulk powders—leading to effects such as enhanced moisture uptake, electrostatic effects, variable flow behavior and consolidation effects.

Conventional powder metallurgy (PM) standards have initially been adopted for use in AM, but they are increasingly seen as insufficient or inappropriate in many instances. ASTM Guide F3049 lists those existing standards that may be appropriate for AM, updates to which are part of ASTM work item WK67454. ASTM WK62190, nearing final review, expands on F3049 but is specifc to PBF.

The AMC is sponsoring a project to evaluate and compare powder characterization techniques, while ASTM is sponsoring a COE project to develop quality assessment guidelines for powder feedstocks (WK66030). Data generated through the ASTM AM powder proficiency test program can be utilized to advance both projects.

Examples of Materials Testing Standardization Activities Addressing Identified Gaps

Powder Sampling

One embodiment of the unique characteristics of powders is that bulk lots may contain significant heterogeneities imparted during manufacturing and/or subsequent handling operations (e.g. self-segregation). Testing data may display high variability if powders are not blended and sampled correctly. ASTM B215, ISO 3954 and MPIF 01 provide existing PM standards for powder sampling, which may be sufficient for most virgin powders. However, sampling of recycled powders and blends remains an identified gap.

Composition

Chemical analysis techniques for metal AM raw materials are largely the same as used in conventional manufacturing. Existing ASTM E01 and MPIF test methods have proven sufficient for ferrous, nickel, titanium, aluminum and other alloys. These methods typically employ XRF, ICP, AA, Spark OES and IGF/Combustion techniques. SEM-EDS analysis can be conducted on particle surfaces or cross-sections, although the size of the population sampled is very limited.

Particle Size Distribution

Existing ASTM B09 PM, ISO and MPIF 05 particle size methods for metals include sieve, laser scattering and air permeability techniques, while ISO provides for material-nonspecific scattering/diffraction methods and image analysis methods (ISO 13322-1 and -2).

Particle Morphology

Standardized particle morphology terminologies for powders are defined by ISO 9276-6 and ASTM F1877. For AM applications, ASTM F3049 mentions the use of light-scattering techniques and image analysis, while WK67454 indicates SEM as the preferred technique. These techniques are disadvantageous considering they utilize 2D images and/or geometric equivalences for representing complex, 3D morphologies. SEM is particularly limited by small sample representation.

However, ASTM B922 provides for analysis of metal powder specific surface area by gas adsorption (nitrogen or krypton), while ISO 9277 applies to general materials. Specific surface area measurements have the advantage of being able to probe bulk quantities of powder, represent all three dimensions of particles and provide quantitative measurement data. Referred to as “BET surface area,” this parameter has been quantitatively linked to many different morphological features. For example, the dramatically different particle morphologies resulting from water-, air- and inert gas-atomized processes are easily distinguished by BET surface area measurements.

Powder Bulk Moisture

As previously described, the nature of powder materials often results in disproportionate uptake of ambient moisture compared to a given material in other forms. This is especially true for particles with surface roughness, defects or other morphologies that produce additional surface area. In metal powders, even very small amounts of moisture (<0.5%wt) can affect oxidation, spreading and densification. Researchers at McGill University have demonstrated the significant impact of ambient lab humidity on powder flow analysis.

While conventional oven-based methods exist for determining moisture content in powders, the techniques are time-consuming. Titrations such as the Karl Fisher method are water-specific and very accurate, but are complex and laborious. Newer generation halogen-IR type moisture analyzers and/or those based on relative humidity in gas flow may prove useful.

Nonetheless, this topic is not being individually addressed by any current programs, and so remains a significant gap, requiring coordination of one or more interlaboratory studies.

This year marks a significant achievement for NSL

The nuclear power industry relies heavily on materials